Make sure you haven't got the discount earlier.

Parts That Fix Hotpoint Dryer HTDX100EM8WW Marks left on clothes

Marks left on clothes is a commonly reported symptom for the HTDX100EM8WW Hotpoint Dryer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your HTDX100EM8WW Hotpoint Dryer that will fix Marks left on clothes. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

This is a duct felt seal for a dryer. The duct felt seal allows the front-load dryer drum to glide smoothly on the front panel. Your dryer will not function properly if the drum felt seal is compromised. Disconnect power to the dryer before completing this repair. You will need to remove the front of the dryer to gain access to the felt seal. This felt seal may differ in appearance from your original but will function the same as your original. This is an OEM replacement part that is sourced directly from the authentic manufacturer.

Replacing your General Electric Dryer Duct Felt Seal

Customer Repair Stories

Dryer leaving stains on clothes

-

Tahir from ARLINGTON, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

the felt in front door worn out

-

gerard from goldsboro, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

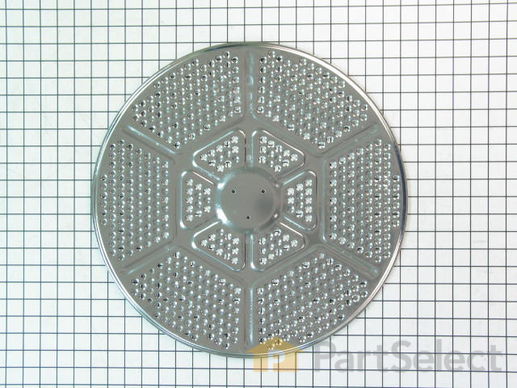

The lint chute assembly houses the lint filter and channels exhaust air from the drum to the blower wheel.

Replacing your General Electric Dryer Dryer Lint Chute Assembly

Customer Repair Stories

a lot

-

Craig from HOPKINS, MI

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Catching clothing and reping

-

Jose from LILBURN, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

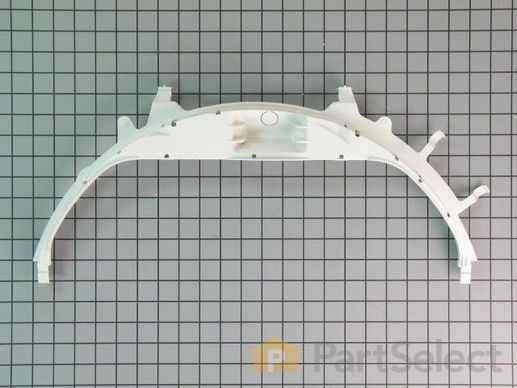

This drum glide bearing is an authentic OEM replacement part that is compatible with dryers. It is white in color and made of highly durable plastic. The bearing allows the drum to rotate smoothly and dry your clothes thoroughly and evenly. It keeps the drum stable and protects it from excessive friction damage. Over time, the bearing may wear down or break due to normal aging or wear from repeated use. If the bearing is no longer able to support the drum, you will likely notice unusually loud grinding or squeaking noises from the dryer. You may also notice increased drying times due to poor drum rotation. Inspect all the bearings on your dryer, as they tend to wear down at the same time. Each drum glide bearing is sold individually.

Replacing your General Electric Dryer Drum Glide Bearing - White (Sold individually)

Customer Repair Stories

Dryer was making noise

-

Maurice from MINERAL SPGS, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

This OEM replacement dryer slide bearing is white in color, and approximately 3 inches long. The slide bearings are supportive linings for your dryer. If they have eroded, or are damaged, the drums will scrape against metal during the drying cycle which will produce a squealing, or scraping sound.

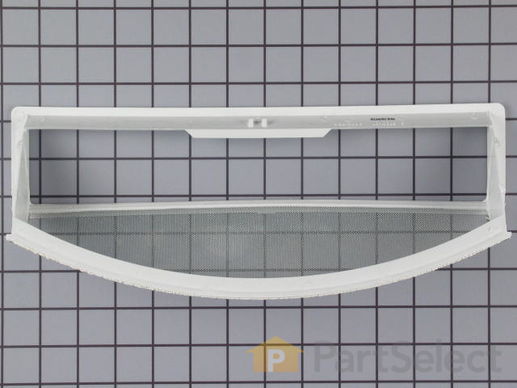

This is a lint filter screen that is used for many dryers. It has a metal screen with a white plastic frame, and is approximately 13 inches wide. This part is sold individually. The lint filter traps lint while clothes are being dried and prevents the lint from building up in clothes and internal parts of your appliance. Neglecting to clean your filter on a regular basis can negatively affect the operation of your dryer and is also a fire hazard. Be sure to clean your filter on a regular basis. Installation is easy, simply slide the filter in and out of the filter slot.

Customer Repair Stories

new lint filter

dryer that is at least 10y/o. it came to me by FEDEX,

in 3 days. i threw out the old one and put in the new

one. easy peasy. i will say that this website had what i

wanted and got it to me very quickly. good job by

PARTSELECT......

-

william from simi valley, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

replacement of holed lint screen

-

Mark from Clarksville, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Note: The drum slides should also be replaced when your replacing the drum bearing. Slides are NOT included. This part helps your dryer operate as quietly as possible.

Replacing your General Electric Dryer TOP BEARING

Also known as Drum Mounting Hub.

Customer Repair Stories

Heat deflector was covered in melted plastic

-

Charles from Alexandria, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Deflector was covered in burnt something.

Had I had the proper tools the repair would probably have taken 30 minutes or less.

-

Richard from San Antonio, FL

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Wrench set